| Building My Dream Kiln II

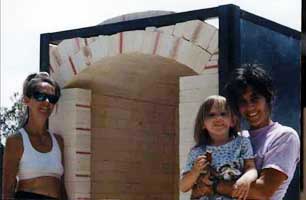

Michelle Lowe of Desert Dragon Pottery describes building her 'Dream

Kiln' (Part 2)

Then I would put the frame pieces

together and tell him where to weld. Another friend of mine

volunteered to be a third hand the two days we spent welding,

and her help was invaluable. I started the frame by building

three cross-layers, the bottom, the layer that holds the brick

and the top, and then we attached uprights to put it together.

|

“Cyndi

volunteered to be a third hand the two days we spent welding,

and her help was invaluable.” |

The cart was then built, upside-down, and set up on

unattached tracks to attach the door frame and test it out.

|

The next thing I focused on was the burner system.

This welding job was pretty special, it needed to be sealed

totally for the gas line. I called my gas company (propane)

and they directed me to someone who could fabricate what I wanted

to build.

|

|

| I took the parts out, laid it out for the guy

and two days later he had built it and air tested

it for me. I bought the actual burners themselves by mail from

a source in Los Angeles. Then, the propane guy came out, scoped

out the job and came back and connected the venturis to the

system. |

|

At this point I also ordered sheets of galvanized

steel for the outer surface of the kiln. It serves both functionally-holding

the thermal insulation and bricks in and visually, being much

more attractive to look at than the outer layer of the kilnwall,

which is rigid thermal insulation. When that was ready, I hired

a welder from the want ads, to come and fix a few minor adjustments

and put the galvanized steel into the frame. Unfortunately,

the film was defective from this point 'til after the kiln walls

and chimney are bricked.

|

|

|

Bricking

The first thing I did, to start filling in this blank frame

I had constructed, was to line the sides and bottom layers with

thermal insulation. This kiln design has six burners coming

up from the bottom along both sides. I had to cut the port holes

for the burners in the insulation. It was then I realized that

I had miscalculated and made the burner assembly 5.5" too wide,

necessitating a crosspipe being shortened. Lining the kiln was

easy, as the insulation material is much like layered cardboard

and very easy to cut to fit. The only drawback about working

with the insulation is the itchy dust. When the insulation layer

was all in, we started on the walls. The side walls went fairly

quickly and smoothly but the back wall, with the flue, chimney

and damper to think about went a bit more roughly. I was unhappy

with the back wall after the first try. After discussing my

design with an online friend, in particular the meeting of the

cart and the kiln at the back wall, I decided to take the back

wall down and rebuild it, changing the cart/kiln seal and fixing

the crookedness that bothered me. The second incarnation of

the back wall was much better. My flue design is Nils Lou's

venturi design from The Art of Firing, with a horizontal

damper up above the flue.

|

|

| Next I had to build my arch. This was a challenge.

I wrangled Gary to help me build an arch form out of plywood,

cutting arcs of wood and running strips lengthwise. I used Fred

Olsen's book to determine how many bricks I should need. I decided

to cut the sideskews for the arch, as I had forgotten to order

them with my other brick. |

|

| “Rusty

Wiltjer's suggestion to load the cart with hardbrick on top

to hold the softbrick in place...was brilliant!” |

I was confused, at first, as to how

to determine the skew brick shape, but after some discussion

of the process with friends I bought a mitering square and laid

the archbrick out marking the skew angle on paper, which I used

as a guide to set the mitering square used to mark each skew

brick.

|

> continue

> previous

More Articles

|