| Building My Dream Kiln

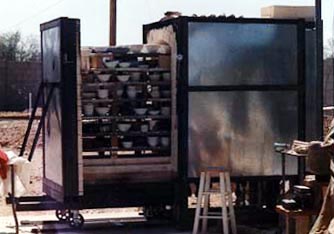

Michelle Lowe of Desert Dragon Pottery describes building her 'Dream

Kiln' (Part 1)

Background

For several years, I had dreamed of building a downdraft, gas-fired

car kiln. However, life kept getting in the way.

When I first started my home pottery studio, I had a small updraft

gas kiln. I sold it when we decided to move 1300 miles away from

Arizona to Nebraska (another long story). We didn't plan on living

in Nebraska for only two years, but circumstances would lead us

back to Arizona, and what with moving expenses and getting settled

(and having a baby) the gas kiln never materialized while we lived

on our farm in Nebraska. Gary was born and raised here in the desert

and didn't realize how homesick he would be for the climate. He

was really hoping to re-re-locate, back here in the Phoenix area

and asked me to consider the major move back (ever move a pottery

studio? It's like moving a mountain, and twice in two years!) I

thought about it, and although I enjoyed living near my family in

Nebraska (my mom, dad and siblings, etc.), I knew that for many

reasons it was probably best for our family to come back to this

area. Ever one to capitalize on circumstance, I told my sweet hubby

that although I am easy, I am not cheap and could this agreement

include the promise of my dream kiln, even if it cost upwards of

$5000 to build? He quickly agreed.

That was in early 1994; we were back in Phoenix by May of that

year. After settling into our new home, (the hobby farm described

back on my main page) Gary really wanted to open a second store

for our music business, and being the ever-supportive partner that

I am, I agreed. That put the kiln-building off awhile, because of

cash considerations. The new store opened in June of 1996 and didn't

take long to pull its own weight. Later in that summer of 1996,

my wonderful, supportive husband and partner told me to 'go for

it'. So, I started researching, thinking about, and planning my

dream kiln! I had no idea what I was in for, but it's been an amazing

experience.

Planning stage

I went to the library and read books about kiln building, and bought

a couple books for my personal reference. I looked at car kilns

of several different designs and talked to many potter friends,

in real life, and online, about car kilns. I finally decided to

go with using a design a local potter had built last year and is

having great success with. I looked at his kiln and measured and

adjusted to make my kiln a bit smaller. I talked with him at length

about the procedure he went through building his kiln, the steps

he used. I drew sketches of the parts of the frame that I thought

would need clarification when we built mine. I measured and re-measured

every dimension I could think of that I might need while at home

building. This planning and thinking stage took longer than I anticipated

but I was rewarded by the ease of execution when I finally got to

the building stage.

Beginning

the kiln--the frame Beginning

the kiln--the frame

It took me awhile to find someone to agree to weld the frame together

for me. I was willing to hire someone, but not sure where to look

for a reliable welder. A friend of a friend decided that he would

supply his expertise and do the welding for me, if I directed, because

he knew nothing about kilns. I invited him over to see the kiln

that my potter friend had built, to give him an idea of the scope

of the job. Then, after detailed discussion of the frame construction,

I searched out and found a supplier for the steel tubing and angle

iron I needed. What an interesting sight to see giant wet-saws cutting

20 foot pieces of 3 inch tube in half like they were butter. After

getting the steel, I rented a "chop saw" and a generator

powered welder and my welder friend came out for the day. He taught

me how to use the chop saw properly and then grind the sharp edges

off the cut steel with a hand grinder.

> continue

|