| Reducing

in an Electric Kiln

Avoid premature kiln ageing

Many potters, ceramic artists and hobbyists have electric kilns,

but not gas or woodfiring kilns at their disposal. This poses a

problem if you want to create reduction glazes such as copper reds

or celadons. These glazes require a reduction atmosphere, where

the kiln is starved of oxygen. Free carbon in the form of carbon

monoxide is formed. (This is also why reduction firings should be

done in very well ventilated areas. See the Toxic

Materials Database for more info.) This is normally done

by reducing the flow of fresh air to the kin interior, by closing

off the flue (chimney). The oxygen inside the kiln is quickly used

up by the combustible fuel (wood, gas or oil) and different chemical

reactions take place than in an oxidizing atmosphere.

In

the reducing atmosphere, copper forms metallic copper instead of

copper oxide. It is this metallic copper that gives copper red glazes

their distinct color. Iron forms iron oxide (FeO2) in oxidation,

but in reduction, ferrous iron (FeO) is produced, with its bluish,

green or black hues. In

the reducing atmosphere, copper forms metallic copper instead of

copper oxide. It is this metallic copper that gives copper red glazes

their distinct color. Iron forms iron oxide (FeO2) in oxidation,

but in reduction, ferrous iron (FeO) is produced, with its bluish,

green or black hues.

Reducing electric kilns is a problem. It is possible to throw in

combustible materials through spy holes, but this is difficult.

More importantly, the carbon tends to aggressively attack the kiln

elements (heating coils), considerably shortening their life through

corrosion. If creating a reducing atmosphere in an electric kiln

is so damaging, what is the solution? There are two answers to this.

- Artificial Reduction

In artificial reduction, a reducing agent is introduced into the

glaze itself. This is usually silicon carbide (SiC). Silicon carbide

has a strong reducing effect on the other glaze materials. 1.5

- 2 percent should be enough to create the desired effects. The

finest available grade (300 mesh or finer) should be used, so

the material disperses as evenly as possible in the glaze, otherwise

specks may appear. Sometimes bubbling of the glaze may occur (similar

to a crater glaze), then soaking at top temperature is recommended.

- Saggars

You

can make your own special custom containers or lidded boxes in

which you put your pottery along with some combustible material

like coal or moth balls. When the organic material burns, it creates

a localized reduction atmosphere inside the box. You need to work

out the amount - too much will cause blackening through carbon

trapping, too little and there won't be sufficient reduction effects.

Above left: Saggar fired test tile with reduced cone 6 copper

red glaze. You

can make your own special custom containers or lidded boxes in

which you put your pottery along with some combustible material

like coal or moth balls. When the organic material burns, it creates

a localized reduction atmosphere inside the box. You need to work

out the amount - too much will cause blackening through carbon

trapping, too little and there won't be sufficient reduction effects.

Above left: Saggar fired test tile with reduced cone 6 copper

red glaze.

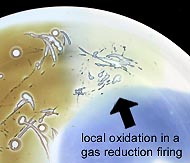

You might think that oxygen will enter the container from the

outside, but that isn't the case. Oxidation and reduction remain

localized. This is also an effect that can sometimes be seen even

in a wood or gas kiln, where there may be areas of local oxidation,

despite an overall reduction atmosphere (see image).

You might think that oxygen will enter the container from the

outside, but that isn't the case. Oxidation and reduction remain

localized. This is also an effect that can sometimes be seen even

in a wood or gas kiln, where there may be areas of local oxidation,

despite an overall reduction atmosphere (see image).

More Articles

Firing Techniques |