| How to Make a Clay Whistle

Technique by Chris Henley

Below you will find a sequence of photographs with accompanying text that describes

the fundamentals of a clay whistle making technique. I discovered

quite by accident sometime around 1970. It is simple and works

every time, if you follow the sequence. However, there are a few

variables that come into play. Generally, the more plastic the clay,

and the smaller the inclusions (grog/sand) the easier it is to form

the more delicate parts. I have never tried this technique

with polymer "clay". However, I have had reports from

others who say they have had some success.

I have tried to point out the other variables as they pertain

to the process in the accompanying text. You will probably have

to fiddle around some to get yours to sound, but don't be discouraged!

I have tried to distill the technique to the essential elements.

It lends itself to considerable variation. So, experiment, push

the limits, keep trying! Remember, it's just clay.

|

|

1. Form a pinch pot. Most

any size will do. Just keep in mind that the chamber size

will be one of the factors that impacts tone. Try to keep

the wall thickness as uniform as possible; it will serve

you well at a later stage. |

|

|

2. Pinch the edges of the

pot together. Just the edges. The purpose here is to form

the basic chamber. |

|

|

3. You are making a hollow

form with as much interior volume as you can. |

|

|

4. "Sew" the edges

together by scoring. |

|

|

5. Smooth the scored edges.

You can use any kind of tool that will accomplish the task.

Just your fingers will do. The goal is to get an air tight,

sealed, hollow form. |

|

|

6. Once you have the form

sealed you can begin to form and shape it. As will become

apparent, the Fat Taco or Empanada shape you end up with

at this stage lends itself well to a variety of designs.

Mine tend toward the organic, or critter forms.

You don't need to do any forming at all

if you just want something that will make a tone (s).

However, if you do plan to form or attach anything, this

is the time to do it. My suggestion is to just learn to

make the whistle and then, when you have mastered that,

Let the Rumpus Begin! Here I'm paddling the shape. You

can be very aggressive or, as a friend of mine says, "Spank

It !" |

|

|

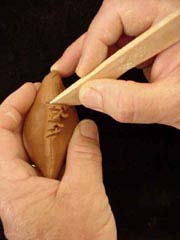

7. When you get the shape

and form you want.....after all the attachments have been

made, then, and only then can you safely pierce the form.

What you see at the left illustrates the tool and the method

I use to form the wedge to split the air. The real whistle

makers have a term for this part of the whistle, but I don't

know what it is. Anyway, take the blunt end of a dowel or

needle tool and, holding it at about a 45 degree angle to

the surface of the form, push it into the interior (between

20 and 60 degrees will work, too). Don't push it all the

way through both sides. It is important that you pull the

tool out at the same angle that you pushed it in. You just

want to put a hole in one wall. A clean, sharp (squared)

edge on the dowel, will produce a clean hole and a sharp

wedge. Be sure you check to see if the little "pill"

of clay that is formed on the end of the tool doesn't re-plug

the hole when you extract the dowel. I like to push the

"pill" into the hollow form and have it as a rattle.

|

Next Page > How to Make a Clay Whistle II

Related Articles

How to Make a Nightingale Cup

How to Make a Puzzle Mug

In Their Cups - The Story of the English

Puzzle Mug

More Articles

|