| Terra Sigillata and Slips

in Woodfiring

Article by Alan Willougby

As

artists we seek the defining characteristics of our individual voices

and the techniques by which to best express this vision. Technique

by itself has little meaning. However, often in the interplay between

vision and technique we are able to take steps forward, at one moment

pushing technique to stretch our vision, and at another pushing

our vision to stretch the technique. Looking back in retrospect,

we are amazed by this evolution. As

artists we seek the defining characteristics of our individual voices

and the techniques by which to best express this vision. Technique

by itself has little meaning. However, often in the interplay between

vision and technique we are able to take steps forward, at one moment

pushing technique to stretch our vision, and at another pushing

our vision to stretch the technique. Looking back in retrospect,

we are amazed by this evolution.

There is an exciting and diverse range of possibilities in terra

sigillatas and slips fired to high temperatures in a wood kiln.

These processes lie somewhere in the middle of the spectrum between

the natural ash glazed pots of anagama firings and the beautiful

more subtle glazed ware fired in wood kilns. In this article I discuss

the technical processes I have been working with in this ‘middle

range’, while referencing the personal and artistic issues which

have taken me on this course of investigation. Additionally, I will

attempt to place these processes within the current woodfiring movement.

Woodfiring has become increasingly popular in the past 10-15 years.

This was witnessed at the 1999 International Woodfire Conference

held at the University of Iowa in Iowa City, Iowa, USA, with many

of the progenitors of woodfiring in both the USA and abroad attending.

It was a wonderful experience to spend several days discussing woodfiring,

making contacts and learning about the pursuits of many fine ceramic

artists. What was somewhat puzzling for me at the conference was

the dominant aesthetic focus on heavy ash build up as typical in

a classic anagama firing. However, beginning with the opening address

by Louise Cort, there was a call for discussion and exchange of

information on glazed woodfired pots and by the fourth day of the

conference the ‘Decorative Treatments: Slips and Glazes’ panel served

as a catalyst for informal discussions on other woodfiring decorative

processes and were a welcome counter balance to the preponderance

of ash glazed pots.

It is quite natural that with increased popularity a movement such

as woodfiring becomes identified with a predominate focus. This

phenomenon is a catalyst for growth but can be somewhat misleading.

There are many other areas of exploration taking place in woodfiring

and with time I am confident that we will see an increase in the

written and visual documentation of these processes. This phenomenon

is reminiscent of the high fire reduction pots which swept this

country in the late ’50s and ’60s which with time expanded into

a wide variety of high-fire options. In retrospect such an initially

narrow focus was a part of the catalyst for change within the ceramics

movement in the US and abroad, contributing to the vitality, growth

and expansion of the studio ceramics movement. Perhaps, with woodfiring,

we are in the early stages of a change which with time will gain

a new historical significance not yet fully comprehended.

Several concurrent issues sparked my interest in woodfiring. First,

I was searching for a firing process in which wet to dry surfaces

were equally pleasing and appealing to the touch, where the clay,

slips and glaze could all be a part of the surface of a piece and

have a tactile appeal. Secondly, I wanted greater involvement in

the firing process. I believe this has been a quest to develop an

understanding of the primary elements in making pots: clay, air,

water and fire. Fire transforms, fire is ritual, fire is a vital

and irreversible part of the process of making ceramics and I was

separated from it through the use of electric and gas kilns. There

is irony for me in the fact that wood has always been a part of

my life but only in the past 10 years have I become attuned to the

importance of wood in firing my pots. As a child and teenager I

was cutting wood for heat and now I have a wood stove in my home.

When I light a fire each wintry night the scent sends me back to

my most recent woodfiring and to my early childhood experiences

and thoughts of transformation and change.

Before

coming to woodfiring, I had worked extensively with slips in high

temperature, mid range, and most recently, earthenware, firing in

both electric and gas kilns. Processes I was working with included

slip-trailing, multiple layering of slips and paper resist. I was

applying slips on leather-hard clay because I liked the integration

and interaction between the clay and slip that was possible when

both were pliable, including carving through the slip into the clay

and scraping the clay up into the slip(s). This process of making

and immediately decorating work requires intense concentration and

focus, and the timing of slip application on the leather-hard clay

is critical (clear glazes are applied later to bring out the colour

in the slips). As I began woodfiring I wanted to simplify my slip

application methods and also take the pressure off having to decorate

the work at the time it was made. I was ready for a shift in my

studio rhythms. Adjusting my slip recipes, I began decorating on

bone-dry greenware. This allowed me to fill my studio with pots

and then focus on their surface treatment. The adjusted slips for

bone-dry clay application held and I was off and running in my first

firing of woodfired pots, combining a clay wash to enhance flashing,

painted slips, slip trailing and glazes. Before

coming to woodfiring, I had worked extensively with slips in high

temperature, mid range, and most recently, earthenware, firing in

both electric and gas kilns. Processes I was working with included

slip-trailing, multiple layering of slips and paper resist. I was

applying slips on leather-hard clay because I liked the integration

and interaction between the clay and slip that was possible when

both were pliable, including carving through the slip into the clay

and scraping the clay up into the slip(s). This process of making

and immediately decorating work requires intense concentration and

focus, and the timing of slip application on the leather-hard clay

is critical (clear glazes are applied later to bring out the colour

in the slips). As I began woodfiring I wanted to simplify my slip

application methods and also take the pressure off having to decorate

the work at the time it was made. I was ready for a shift in my

studio rhythms. Adjusting my slip recipes, I began decorating on

bone-dry greenware. This allowed me to fill my studio with pots

and then focus on their surface treatment. The adjusted slips for

bone-dry clay application held and I was off and running in my first

firing of woodfired pots, combining a clay wash to enhance flashing,

painted slips, slip trailing and glazes.

The aspect of this decorating I did not like was brushing and painting

slips on the bone-dry pots. In the application of the slips there

was a chalky quality in contrast to the natural flow of slips on

leatherhard clay. Additionally, slip trailing across a painted slip

often ended with a clogged slip trailer. Just when I was about to

begin experimenting with additions to the slip recipe to improve

the methods for brushing and painting, I took another turn. On my

previous earthenware pieces I had begun working with terra sigillata

on areas of the pieces where I wanted colour and a satin surface.

I was attracted to the working qualities of terra sigillatas, how

they paint on greenware, as well as the fired sheen so unique to

terra sigillata. Why not try terra sigillata in high fire? With

my first stroke of terra sigillata on a bone-dry greenware porcelain

pot I knew this was going to work.

I have two methods for preparing terra sigillatas. The first is

to mix a large batch of OM #4 Ball Clay and, after settling, ladle

off the water on top and then pour off the fine particled terra

sigillata. With one or two cup quantities of this base sigillata

I mix high temperature Mason Stains (see formulas). My other approach

is to mix coloured terra sigillatas using different clays and adding

oxides. After leaving it to settle for several days, ladle off the

water and pour off the fine particled terra sigillata. Depending

upon the oxides used it is sometimes a good idea to ball mill the

mix before decanting to eliminate streaking and spotting from the

oxides in the sigillata. Both methods result in terra sigillatas

that high-fire to a rich tactile surface, somewhere between a slip

and a glaze. The possibilities of colour are endless. In applying

terra sigillata, I use both smaller paint brushes and sponge brushes.

It is important to apply the sigillata with a firm, distinct stroke,

returning to overlay where necessary. At the same time I don’t belabour

the application, being careful not to build up too heavy a thickness.

Remember, we are applying a wet sigillata to a dry (greenware) pot

and to achieve a strong adhesion the sigillata cannot be too thick

or it will have trouble holding on to the clay once it dries. On

top of the terra sigillatas I often use slip-trailing to create

a series of lines, outlines, symbols, marks, etc. These coloured

slips are slip-trailed on the clay, on a wash over the clay and

on terra sigillata. Because of the fine particle character of terra

sigillata, slip trailing moves smoothly across the sigillata surface.

As an artist I can’t resist decorating on a three dimensional surface.

I look forward to the exploration and risk involved in finding the

right drawing, pattern or mark(s) for the right form. Some forms

dictate a minimum of decoration and other forms reach out for multiple

images, patterns or marks. Additionally, there are often multiple

solutions to the same form and it is in the dynamic interaction

and relationship between form selection and surface treatment where

we find our individual expression. The strongest pots bring these

two components of form and surface treatment together in a unification

unique to the creator ? influenced and affected by time and place,

and the materials, forming methods and firing processes used. The

range of decorating processes I use in woodfiring work well individually

and together. I have created pots with only a wash and glaze, pots

with only terra sigillatas and slip, and pots which include a wash,

terra sigillatas, slips and glaze. In surface treatment there is

opportunity for a simple, direct statement and the opportunity to

develop a more complex multiple layered effect.

I have been firing my pots in kilns which are based on the noborigama

kiln design. My interest and pursuit of woodfiring is directly connected

to the emergence of noborigama style kilns in the US. Any type of

woodfiring is labour intensive, but these kilns are efficient, suitable

for firing in several days or one day. They have an ability to be

both responsive and forgiving, the atmosphere can be heavily reduced,

neutral or oxidised. As I become familiar with the unique nature

of the kiln and each chamber, I stack the pots according to the

desired effect sought, considering hotter and cooler locations,

heavier and lighter ash build-up, heavier to lighter reduction locations

(in a reduction firing) or neutral to oxidising locations (in a

neutral firing). With an interest in colour and the use of specific

clays, washes, slips, terra sigillatas and glazes, the firing atmosphere

becomes an important consideration. Colour is influenced and affected

by reduction, neutral firing and oxidation. Along with understanding

these atmospheres to affect colour, an important part of woodfiring

is learning to work with the natural flame paths which deliver ash

to the pots and create flashing on the sides of pots. This ‘mark

of the fire’ speaks of the cycles of nature and of transformation.

Flashing and ash build-up across washes, terra sigillatas, slips

and glazes can evoke a multi-dimensional world.

Woodfiring includes a broad range of surface treatments from natural

ash glazing to washes, terra sigillatas and slips to classical glazes.

Within this realm there is incredible variety to the processes and

techniques which can be explored, and through this exploration gain

knowledge of oneself and the world in which we live.

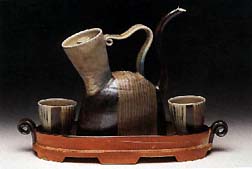

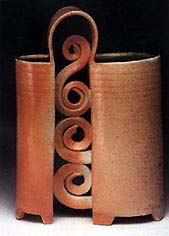

Alan Willoughby is a studio potter from southern New Jersey,

USA, and Executive Director of the Perkins Center for the Arts,

Moorestown, NJ. Photographs by John Woodin, Philadelphia, Pennsylvania,

USA.

Slips

Cone 9-11 slips are for bone-dry greenware application. Colour quality

comes from firing to cone 9-12 in a wood/salt kiln.

Alan’s Cone 9-11 White Slip Colour Base

- Tennessee #10 Ball Clay 11.5

- Edgar’s Plastic Kaolin 5.5

- Calcined kaolin 16.5

- Whiting 15

- Nepheline syenite 23

- Flint (325 mesh) 23

- Soda ash 5.5

- Zircopax 10

To this colour base add high temperature stains 5 - 25%. Add .0125

(1/8 of 1%) Calgon as a deflocculent. Mix calgon in warm water before

adding dry mix. Four that I use:

- 6600 Black 10%

- 6313 Medium Blue 5%

- 6131 Titanium Iron-brown 20%

- 6485 Titanium Yellow 25%

Glazes used in wood/salt kiln

Cone 9-11 Transparent—1-2-3-4

Tennessee #10 Ball Clay 10 Whiting 20 Flint (325 mesh) 30 NC-4

Felspar 40 Bentonite 4

Cone 9-11 Rob’s Green

- Edgar’s Plastic Kaolin 16

- Flint (325 mesh) 45

- Whiting 28

- Nepheline syenite 11

Add:

- Copper carbonate 7%

- Black copper oxide 3.7%

- Bentonite 2%

Cone 10-12 Vinny’s Green - this glaze likes heat.

- G-200 Felspar 41

- Whiting 21.5

- Edgar’s Plastic Kaolin 21.5

- Flint (325 mesh) 16

- Rutile (light) 3

- Copper carbonate 1.5

Originally published in Ceramics

Technical. Reprinted by permission.

More Articles

|