| Visible

Crystals

Janet Hamer outlines the new glazes of Avril

Farley and describes how these sculptural crystal shapes are formed

Reproduced with kind permission

of Ceramics Technical.

© Ceramics Technical

and Janet Hamer.

We

are all keen to make a mixture of minerals, take it to a temperature

and wonder at transformations –or we should be. It is like

pushing seeds into a garden and, with a bit of nurture, flowers

open and spread their colours. Making crystals is like that: a lot

of science, patience and beauty. Large crystals grown in a glaze

even look like flowers. They often resemble lichens and three-dimensional

fans and feathers. We

are all keen to make a mixture of minerals, take it to a temperature

and wonder at transformations –or we should be. It is like

pushing seeds into a garden and, with a bit of nurture, flowers

open and spread their colours. Making crystals is like that: a lot

of science, patience and beauty. Large crystals grown in a glaze

even look like flowers. They often resemble lichens and three-dimensional

fans and feathers.

Crystalline glazes are those in which the oxides in the melt reform

in new associations as the glaze cools to give a glass with crystals

visible at the surface. A mass of crystals too small to be seen

individually can give opacity and matt surfaces. Larger crystals

can be grown upwards of 15 cm, appearing to float in a glassy matrix.

These wonderful shapes, of distinctly different colour from their

background are the result of manipulating the glaze formula and

the cooling rate of the kiln. This is the science and the patience.

The beauty manifests itself magically from these processes.

Typical crystal shapes are soft flat rounds which may impinge

on each other in clusters, modifying the symmetry. A central star

or bundle of needles can be seen in a smooth area before a fibrous

ring fans out as a halo. Further haloes edge the shape where it

meets the background glaze or matrix. The whole of this shape is

coloured by the penetration of a colouring oxide into the crystal

and is clearly seen against the background. There is often a delicate

fringe of a slightly different colour where crystal meets matrix.

The haloes can be deliberately placed centrally or around the border

of the crystal. Where the glaze is thicker, as in the well of a

bowl, the three-dimensional forms can be seen as fibrous fans filling

the depth. Time is needed during the cooling of the glaze for crystals

to form.

In the early stages of cooling, if the temperature is held around

1090ºC for approximately two hours, the crystals begin as simple

needle shapes. These can fan out at each end into ‘double-axehead

shapes’. These attractive and intriguing crystals can be retained,

frozen at this stage by cooling the kiln rapidly after this growing

period. The fuller rounder shapes develop when the temperature is

subsequently maintained for further crystal growing periods. These

periods, or pauses, are programmed into the cooling graph of the

kiln controller and may last from three to eight hours.

| Porcelain

is often the choice of body for use with crystalline glazes.

Bright colours show up welland there is little contamination

from the bodyduring the slow cooling. The main glazeconstituent

is a frit. This provides most of theglass which melts at the

appropriate temperature.

Ferro frit 3110 analysis

Silica (Si02) 69.8Sodium oxide (Na2O) 15.3Calcium oxide (CaO)

6.3Aluminium oxide (A12O3) 3.7Boron oxide (B2O3) 2.6Potassium

oxide (K2O) 2.3

Avril Farley glaze recipes:

1. Ferro frit 3110 47

Calcined zinc oxide 23 Calcined china clay 3

Flint 23 Titanium oxide 4

2. High Alkaline Frit 2275 46

Silica 18

Zinc oxide 24

China clay 40

Titanium oxide 8

Oxides of copper, cobalt andmanganese are added totalling

a maximum of 8%. |

Each glaze component has a particular role

but these are not single elements and their contributions

overlap. The frit is designed to make the glaze melt quickly

at top temperature. This presents a fully molten mix which

is immediately ready for the new bondings to be formed. The

rapid firing up to and down from the top temperature avoids

the formation of a body-glaze layer which inhibits the forming

of large crystals. Zinc oxide combines with flint and provides

the zinc silicate for large crystals. The china clay gives

stability and hardness to the final glaze. The flint is almost

pure silica. It can be a different type from that provided

by the frit for the main glassy ingredient and supplies nuclei

for crystals. Titanium oxide contributes nuclei as ‘seeds’

for the initiation of crystals. It also brightens colours

and assists the movement of colour in the glaze.

The oxides (or carbonates which lose their carbon and excess

oxygen in the fusion) of copper, cobalt and manganese, colour

the glaze matrix, or the crystals, or sometimes both in specific

ways, according to their ‘field strengths’.

Crystals grow in the cooling glaze by the isolation of particular

oxides from the surrounding glaze. Zinc silicate is most often

the material of large crystals. In the molten glaze the molecules

of the glaze minerals are loosened from their original combinations

giving a fluid mixture of individual molecules. In a normal

glaze, as cooling begins, these molecules link together to

form irregular chains. This creates the amorphous substance,

glass. For crystals to develop, the temperature is held for

those periods when molecules orientate into more specifically

organised chains. They establish bonds which produce lattice

structures which are the framework of crystals. The unsatisfied

valencies existing in the melt link to sites where they form

new combinations. |

|

Left: This complex crystal shows the fan-like

growth and three-dimensional appearance in the depth of glaze.

The blue staining ofthe crystal is incomplete due to the small

percentage of cobalt oxidein the recipe. The pot was glazed

first with a Ferro Frit-based glazeand over this a High Alkaline

Frit 2275 base glaze. Each onecontained 0.5% cobalt oxide

and 3% manganese carbonate.

Crystal formation is a selective process. As some constituents

are precipitated, the remaining matrix is changed. The isolation

of some of the constituents upsets the previous balance. Some

of the remaining oxides can no longer remain unattached. They

combine as larger molecules and stiffen the matrix. The matrix

then sets quickly and crystals can no longer develop. |

There

are orders and preferences for how the molecules which jostle freely

in the melt will re-bond into new lattice structures. Each element

is characterised by a value number or valency. This number is based

on the number of electrons in each atom and establishes its combining

power. Valencies are balanced to match. For example, hydrogen is

1, oxygen is 2, therefore two hydrogen atoms are needed to match

one oxygen, giving the familiar chemical symbol H2O (water). There

are orders and preferences for how the molecules which jostle freely

in the melt will re-bond into new lattice structures. Each element

is characterised by a value number or valency. This number is based

on the number of electrons in each atom and establishes its combining

power. Valencies are balanced to match. For example, hydrogen is

1, oxygen is 2, therefore two hydrogen atoms are needed to match

one oxygen, giving the familiar chemical symbol H2O (water).

The elements which are frequently used to colour the zinc silicate

crystals are cobalt, manganese and copper. They have valencies of

cobalt 2 and 3, manganese 2, 3 and 4, and copper 1 and 2. They have

2 in common with zinc and therefore compete for the same sites when

new combinations are being formed. In the Periodic Table the colouring

elements are grouped together as ‘transition’ elements.

Other elements in this grouping have similar properties and are

likely to be useful in a similar way.

There are further rules which govern the selective process by which

crystals are positively coloured, why blue on an ochre ground predominates

whereas green can be subtly combined. The electrons of the atoms,

which are negatively charged, exert forces of attraction or repulsion

on others which are in close proximity. This activity is referred

to as an energy field. Colour separation is explained in the following

extract from the section on crystalline glazes in The Potter’s

Dictionary:

In order to colour the precipitating zinc-silicate crystals,

the colouring oxides must be able to fit into the lattice structure.

To enter the crystal, the metal colouring atom must be able to

occupy one of the six sites otherwise held by zinc in the zinc-silicate

lattice. Cobalt, nickel, copper, iron and manganese are transition

metals and are adjacent to zinc in the periodic table. They are

polyvalent and can be divalent to match zinc. Their atom sizes

are also similar to that of zinc. Therefore all these metals can

enter and colour the crystals.

| Right: The colours here are from ilmenite (FeTiO3,

iron and titanium oxide) andcerium oxide (CeO2) which has properties

similar to tin oxide. |

|

The reason for the order of precedence is that they have different

liquid-to-crystal partition co-efficients, or field strengths. Cobalt

oxide and nickel oxide have high field strengths. Manganese oxide

is intermediate and copper oxide is low. Zinc oxide has a higher

field strength than does copper oxide and, therefore, copper oxide

tends not to partition strongly but will stain both the matrix and

the crystals at the same time.

Avril Farley has been making crystal-glazed ceramics for four years.

Her workshop is a small, neatly organised outbuilding. The workroom

and its surrounding work areas are next to the cottage where Avril

lives with her husband, Ken. The setting is rural Gloucestershire

in the Royal Forest of Dean, England. The cottage and workshop stand

above a delightful sunny garden which slopes steeply down to a stream.

The slope and footbridge are the route up and down which all clay,

equipment and finished work must be portered. In the late 1780s

this cottage was a pub humorously named ‘The Sow with Three

Tits’. Here cider was made and served to the iron workers

who toiled immediately opposite, across the stream.

Avril Farley’s production consists of thrown plates, bottles

and bowls. She prefers Limoges porcelain body, from Potterycrafts.

She uses a Mervyn Fitzwilliam Craftsman wheel. She does a small

amount of turning to make neat footrims which accommodate the inevitable

glaze run and grinding. The two 4 1/2 cu ft electric kilns are fired

at night for economy with the use of two Cambridge 401+ controllers.

She usually achieves two biscuit and one glaze per week, alternating

with one biscuit and two glaze firings.

|

|

| This fringe-edged crystal is approximately 4 cm across.

Itappears in a glaze with 1.5% vanadium oxide (V205)

and1.5% ilmenite in a Ferro Frit base glaze. |

This glaze shows how copper oxide can give a green stain

toboth crystal and matrix. The glaze has 3% copper oxide and

3% barium carbonate (BaCO3). The barium carbonate

shiftsthe colour towards turquoise. |

Glazes

are brushed on, thicker above than below to allow for considerable

glaze movement. Calcining the zinc oxide removes water and helps

to avoid flaking of the glaze. A binder, ‘CMC’, is used

to make the glaze less friable. Every pot is fired on a ‘catcher’

made to measure. Surplus run off glaze is contained by the ‘catcher’

which must be separated after firing. Glaze and foot are then ground

smooth. This is a demanding process requiring specialised grinders

for the particular shapes and a skilled operator who is efficiently

clad in protective clothing, goggles and helmet. Every firing contains

tests. New shapes show their effect on glaze run and positioning

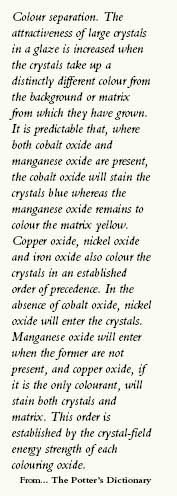

of crystals. The permutations seem infinite. The diagram shows how

felspar, Alkaline Frit 2275 or Ferro Frit 3110, sometimes layered

cobalt oxide can replace zinc together. Firing is usually to between

1245ºC and 1265ºC with many growing pauses in the cooling

cycle. The first at 1080ºC for 30 minutes followed by a pause

at 1060ºC for 30 minutes, then a rise to 1080ºC again.

There may be as many as six pauses but Farley also likes to vary

the timing of of zinc silicate. These periods to give more interestingly

placed haloes. Glazes

are brushed on, thicker above than below to allow for considerable

glaze movement. Calcining the zinc oxide removes water and helps

to avoid flaking of the glaze. A binder, ‘CMC’, is used

to make the glaze less friable. Every pot is fired on a ‘catcher’

made to measure. Surplus run off glaze is contained by the ‘catcher’

which must be separated after firing. Glaze and foot are then ground

smooth. This is a demanding process requiring specialised grinders

for the particular shapes and a skilled operator who is efficiently

clad in protective clothing, goggles and helmet. Every firing contains

tests. New shapes show their effect on glaze run and positioning

of crystals. The permutations seem infinite. The diagram shows how

felspar, Alkaline Frit 2275 or Ferro Frit 3110, sometimes layered

cobalt oxide can replace zinc together. Firing is usually to between

1245ºC and 1265ºC with many growing pauses in the cooling

cycle. The first at 1080ºC for 30 minutes followed by a pause

at 1060ºC for 30 minutes, then a rise to 1080ºC again.

There may be as many as six pauses but Farley also likes to vary

the timing of of zinc silicate. These periods to give more interestingly

placed haloes.

Farley declares her approach to ceramic chemistry was instinctive.

From a nonscientific early career she is now developing a firm understanding

of chemistry through methodical practice and application. She enjoys

the discipline which the creation of crystalline glazes demands.

In a detailed directive to herself, ‘The Learning Curve’,

she stipulates every practical rule steering a controlled course

through trial and error progress.

Record keeping is unquestionable. Glaze making is precise and meticulous

with thorough attention to care of equipment. Firing records include

identification of all tests, positions in the kiln, weather (for

its influence on cooling rates), temperature readings and digital

pictures are stored. Suggestions for variations on every aspect

of the making follow with practical guidance for control of glaze

fusion, and ending with warnings against impatient kiln opening.

Avril Farley is currently experimenting with more materials based

on elements from the lanthanoid series sometimes called ‘rare

earths’.

Janet Hamer, with co-author Frank Hamer,

are the compilers of The Potter’s Dictionary of Materials and

Techniques now in its 5th edition (A & C Black).

More Articles

|