| Oil Spot Glazes

by John Britt

Most ceramics glazes are simple to formulate and very easy to

fire. But there are some glazes and glaze effects that have the

reputation of being elusive or at least difficult to obtain. This

was certainly the case early in the 20th century with copper reds

and celadon blues. These glazes had a history of secrecy and myth

surrounding them. One story even claimed that a Chinese emperor

had slaves thrown into the kiln during the firing in order to produce

the elusive copper red. Thankfully, that was found to be unnecessary,

because we learned that reducing the kiln early in the firing produced

beautiful copper reds. Oil spot glazes also have the reputation

of being elusive but, as I will show in this article, they are very

easy to create, once you know the process which makes them work.

|

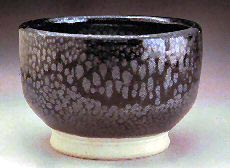

Oil spot tea bowl, John Britt, 2004, dirty porcelain,

cone 11 gas oxidation,

multi-fired, 4” x 3” x 3”

|

The

most important factor in obtaining oil spot glazes is firing in

an oxidation atmosphere. This cannot be overemphasized. Oxidation

is essential because of the mechanism by which the oil spots are

created. Simply stated, the red iron oxide molecule, Fe2O3,

will let go of an oxygen atom at approximately 2250° F (1232°

C). At this temperature, the red iron oxide molecule cannot maintain

its complex structure and will release an oxygen atom to become

the simpler FeO molecule, or black iron oxide. As the oxygen leaves

the red iron oxide molecule it bubbles to the surface of the molten

glaze, dragging a bit of iron with it (image on left). When it reaches

the surface and leaves the glaze it deposits the “spot”

of iron which creates the characteristic oil spot look. However,

if the glaze is reduced early in the firing cycle, the red iron

oxide will already have changed into black iron oxide, and there

is no possibility of an oxygen molecule being released later to

create the oil spot effect. So you can see that without an oxidation

firing cycle there will be no oil spot effect. The

most important factor in obtaining oil spot glazes is firing in

an oxidation atmosphere. This cannot be overemphasized. Oxidation

is essential because of the mechanism by which the oil spots are

created. Simply stated, the red iron oxide molecule, Fe2O3,

will let go of an oxygen atom at approximately 2250° F (1232°

C). At this temperature, the red iron oxide molecule cannot maintain

its complex structure and will release an oxygen atom to become

the simpler FeO molecule, or black iron oxide. As the oxygen leaves

the red iron oxide molecule it bubbles to the surface of the molten

glaze, dragging a bit of iron with it (image on left). When it reaches

the surface and leaves the glaze it deposits the “spot”

of iron which creates the characteristic oil spot look. However,

if the glaze is reduced early in the firing cycle, the red iron

oxide will already have changed into black iron oxide, and there

is no possibility of an oxygen molecule being released later to

create the oil spot effect. So you can see that without an oxidation

firing cycle there will be no oil spot effect.

The second most important factor is the glaze recipe. It must contain

some red iron oxide and be sufficiently stiff to hold the oil spots

that are created, but not too stiff to prevent the bubbling out

of the oxygen. Feldspathic bases are perfectly suited to create

oil spots. The following are some excellent recipes:

Bailey’s Oil Spot Cone 10/11

(images 1& 2)

|

|

| 25.51 Custer Feldspar

35.71 NC-4 (Soda Feldspar)

15.30 EPK Kaolin

5.10 Talc

5.10 Dolomite

5.10 Ferro Frit 3110

8.16 Silica

6.00 Red Iron Oxide |

|

| |

|

|

|

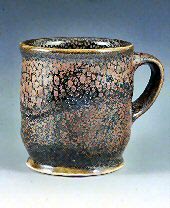

| 1. Cup, John Britt, 2003, Bailey’s

Oil Spot, Grolleg porcelain, cone 11 oxidation, 5” x 4”

x 4” |

2. Detail of Cup, John Britt, 2003, Bailey’s

Oil Spot, Grolleg porcelain, cone 11 gas oxidation, 5”

x 4” x 4” |

John’s Oil Spot #3 Cone 10/11

(Works nicely in electric kilns)

(images 3 & 4) |

|

|

54.62 NC-4 (Soda Feldspar)

29.41 Silica

4.20 Whiting

7.56 EPK Kaolin

4.20 Dolomite

6.72 Red Iron Oxide

4.20 Cobalt Carbonate |

|

|

|

|

| 3. Cup 2, John Britt, 2002, Grolleg porcelain,

cone 10 electric oxidation, 4” x 3” x 3” |

4. Detail of Cup 2, John Britt, 2002, Grolleg

porcelain, cone 10 electric oxidation, 4” x 3” x

3” |

| |

|

| Traditional Oil Spot Cone 10/11 |

Montmollin Oil Spot Cone 10/11 |

80.18 Custer Feldspar

5.66 Silica

3.77 Whiting

4.71 Talc

5.66 Bone Ash

8.50 Red Iron Oxide

|

68.40 F-4 (Soda feldspar)

17.80 Silica

4.90 EPK Kaolin

8.90 Talc

7.11 Red Iron Oxide

2.00 Cobalt Carbonate

|

Each recipe contains a high amount of feldspar, over 50%, some

magnesium oxide, either from talc or dolomite, and between 6.0 -

8.5% red iron oxide. Finally, the glaze needs to be fired between

cone 10 and 11, which I will discuss later.

Another critical factor is the glaze application. If the application

is not thick enough there will be no oil spotting or only very small

spots, while thicker application will give larger spots (see image

5). The final glaze thickness should be at least 1/8” (0.3

cm) and can be as thick as 1/4” (0.6 cm). Usually if you apply

a glaze this thick it will run and fuse the pot to the shelf. But

this does not happen as frequently with oil spot glazes because

the feldspathic glaze is so stiff and, in addition, when iron is

fired in oxidation it is refractory which makes the glaze even more

viscous. This often results in a characteristic hanging glaze drip

at the base of the pot (see image 6).

|

|

| 5. Detail of Oil spot glaze application - thick

and thin, John Britt, 2004 |

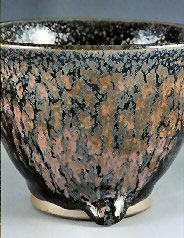

6. Tea bowl, John Britt, 2004, Dirty Porcelain,

cone 11 gas oxidation, 3” x 3” x 3” |

So to summarize, oil spot glazes are usually stiff glazes which

contain red iron oxide and magnesium oxide. The glaze needs to be

applied thick and fired in oxidation to cone 10 or 11. If you follow

these simple steps then oil spot glazes are no more mysterious or

illusive than any other type of glaze. The hurdle that many people

run into is that they want to fire all their work with a standard

early reduction firing cycle. They then put some oil spot test tiles

into this firing cycle, only to be disappointed. Since early reduction

changes the iron they get no oil spots and think it is a difficult

glaze to achieve. But simply switching to an oxidation cycle is

all that is necessary.

Once you know the mechanism which causes the oil spot effect then

producing it is actually quite easy. The difficult but fun part

is then creating variations in the effect and creating forms which

accentuate those effects. For example, you can alter the size of

the spots by varying the length of time it takes to fire from cone

7 to cone 11. If you go slowly, (4 hours), the spots will be larger,

while going faster will give you smaller spots. This is because

the process of releasing oxygen takes time and lengthening the firing

will allow more oxygen to be released, while firing too fast may

leave large unhealed blisters on the surface of the glaze. (This

can be corrected simply by refring the piece.) You can use a slightly

more complicated firing cycle to reduce these unhealed blisters.

In this firing cycle the kiln is in full oxidation to cone 9 and

is then is put into reduction through cone 11. This will help to

stop the bubbling and flux out the surface iron creating a smoother

glaze surface. Draw tiles are extremely helpful to determine when

the firing is complete.

Another interesting variation is the “hare’s fur”

effect. This can easily be created by firing the glazes very hot,

above cone 11, which causes the glaze to run down the side of the

pot, pulling and lengthening the spots. Another interesting variation

is to put a stiff light colored glaze over the oil spot glaze. This

will cause an interesting leopard spotted glaze as the iron is drawn

to the surface (images 7 & 8). These are only a few of the innumerable

variations possible with oil spot glazes.

|

|

7. Incense Burner, John Britt, 2003, Grolleg

Porcelain, Bailey’s Oil Spot with yellow glaze over, cone

11 gas oxidation, 3” x 4” x 4”

|

8. Incense Burner detail, John Britt, 2003,

Grolleg Porcelain, Bailey’s Oil Spot

with yellow glaze over, cone 11 gas oxidation, 3” x 4”

x 4” |

From this article you can see how simple it is to achieve the oil

spot effect. And knowing the process by which it works eliminates

the need to perform any brutal sacrificial rituals on your assistants.

Hopefully, you can use this knowledge as a spring board to create

new and beautiful variations of this ancient glaze.

Article and images courtesy John

Britt. © John Britt 2004. See

more of John's work at his website http://www.johnbrittpottery.com.

John has also got a new book out: The Complete Guide to High-Fire

Glazes: Glazing and Firing at Cone 10, Lark Books, 2004. ISBN:

1579904254.

More Articles

|