| Flambé Magic

Author John Britt investigates the appearance of mysterious crystals

in the glaze slop.

While

conducting researching for my book, The

Complete Guide to High-Fire Glazes, one copper red glaze,

Jeff’s Red, always had a different fired appearance. I initially

attributed this to variations in application, speed of firing and

cooling, or variations in atmosphere. Several months later, however,

when small crystals developed in the glaze slop, I began to wonder.

I first noticed small lumps in the glaze coat on the pot which I

thought were bugs or bits of sawdust which occasionally fall into

an uncovered glaze bucket. However, during the winter while my glazes

were subject to freezing conditions in an unheated shed I noticed

that these were not lumps but were small flat hexagonal flakes of

material which grew larger in size. These flakes were actually small

crystals which floated on or just under the surface of the thickened

glaze. (Images 2, 3) While

conducting researching for my book, The

Complete Guide to High-Fire Glazes, one copper red glaze,

Jeff’s Red, always had a different fired appearance. I initially

attributed this to variations in application, speed of firing and

cooling, or variations in atmosphere. Several months later, however,

when small crystals developed in the glaze slop, I began to wonder.

I first noticed small lumps in the glaze coat on the pot which I

thought were bugs or bits of sawdust which occasionally fall into

an uncovered glaze bucket. However, during the winter while my glazes

were subject to freezing conditions in an unheated shed I noticed

that these were not lumps but were small flat hexagonal flakes of

material which grew larger in size. These flakes were actually small

crystals which floated on or just under the surface of the thickened

glaze. (Images 2, 3)

To figure out what they were, I fired several in a small bowl in

an electric kiln; opening it periodically during the firing I noticed

that they foamed intensely around 600°F (315°C), indicating

that the water of hydration was burning off. They subsequently melted

into a pool of glaze/glass around 1600°F (870°C). While

crystals placed on the side of a pot and gently heated with a propane

torch melted into a liquid and dribbled down the side. After various

enquiries, I concluded that these must be sodium borate crystals,

which precipitated from the glaze mixture as it cooled. One popular

remedy is to sieve them out, re-dissolve them in warm water and

then pour the water back into the glaze, instead I decided to glaze

and fire a pot with as many crystals on it as possible. This produced

a magnificent flambé glazed bowl; the crystals apparently

fluxed out, melting down the side creating the effect.

|

|

| Crystals found in Red Flambé slurry, 6’ x 3’

x 1/8 inch. |

Group of crystals found in Jeff’s Red glaze slurry,

less than an 1/8 inch. |

Still uncertain that the crystals were the primary cause of the

variegated flambé effect rather than the firing cycle, I

fired two similarly shaped pieces on the same shelf, one glazed

with a fresh batch and the other with the ‘crystallized’

batch (Images 15 -17). The effect was only reproduced on the piece

with the ‘crystallized’ mixture, demonstrating that

it was the cause of the variegated flambé surface.

Other glazes

Realizing that crystals were forming in the glaze slop caused

me to examine the other glazes in storage and look for patterns

in the recipes. For my book, I had mixed up approximately 400 glazes,

including copper red, shino, iron, Oribe, and crystalline glazes,

all in quart containers, which were stored in the unheated shed.

Winters in Penland, North Carolina, USA, are moderate, with temperatures

hovering around freezing, but it can easily drop to 10°F (-10°C)

or rise to 50°F (10°C). Glazes stored outside are therefore

subject to a series of freezing and thawing cycles from October

to March.

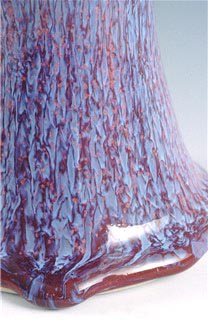

The crystals mainly occurred in glazes with borates, or with borates

and lithium carbonate, and varied from 1/2” (1.3cm) thick

by 2” (5cm) in diameter (Images 2, 3, 4, 5 and 10) to some

that were so small it felt like sand in the glaze. Others covered

the top of the 5” (13cm) container with a thin matrix of crystals.

Most were an opaque white but a number were red from iron oxide

or green from copper carbonate being caught up in the crystal (Images

7, 9). To isolate their effect, some of the larger crystals were

placed on the sides of pots and fired to cone 10 (Images 1, 6 and

8).

|

|

| Crystal found in Jeff’s Red glaze slurry, ½”

x ½” x ¼”. |

Bowl with crystal’s found in Jeff’s Red placed

on rim, reduction, Grolleg porcelain, cone 10. |

|

|

| Stem cup with fresh mix of Jeff’s Red fired in reduction

to cone 10, on Grolleg porcelain. |

Stem Cup with crystallized mix of Jeff’s Red fired in

reduction to cone 10, on Grolleg porcelain |

Since there are over 120 known borate mineral formations and I

decided to have mine analysed by X-ray Diffraction (XRD) and found

that some did contain a type of borax (Na2B4O5(OH)4·8H2O),

while others contained lithium borate hydrate (Li2B2O4·16H2O)

along with miscellaneous minerals like quartz, feldspars and other

trace materials. The crystals occurred mainly in batches of copper

red glazes, including Jeff’s Red, Mary’s Surprise, Purple

Red, Splotchy Lavender and Purple Sludge, but also in VC Matte Turquoise

and Karen’s Starshine, as well as many of my raku glazes.

Each recipe contained borates, either from natural sources (gerstley

borate or its substitutes) or frits, demonstrating that many frits

(Ferro 3134, 3185, 3195, 3191, or Pemco P-54, etc) are slightly

soluble in water.

It is evident that the flambé effect in Jeff’s Red

was caused by soluble materials migrating into crystals as the slurry

cooled. This meant that the mesh size of soluble colour enhancing

oxides, like lithium, sodium and boron, was increasing and that

new combinations of materials were forming with higher concentrations

of colorants, like copper and iron. Firing them on the pot created

areas of greater concentration of those materials.

Solubility

All ceramic materials have physical and chemical properties that

will have an effect on glazes, including mesh size, melting and

volatilisation point, surface tension, solubility, etc. One key

property is solubility, which is the ability of a material to go

into solution at a given temperature. Soluble and slightly soluble

compounds include borax, soda ash, pearl ash, Epsom salts, wood

ash, gerstley borate (and its substitutes), copper sulphate, nepheline

syenite, lithium carbonate, barium carbonate, etc. Solubility usually

varies with temperature. For example, 23.3g of sodium tetraborate

(borax) will dissolve in 100g of water at 140°F (60°C).

But at 32°F (0°C) only 1.3g will dissolve. So in a glaze

made up at 140°F (60°C) and slowly cooled toward freezing,

22g of borax will precipitate out. Also, if the volume of water

is reduced, from evaporation, some of the solute will fall out of

solution. But rather than fall to the bottom of the bucket, the

charged ionic particles can be attracted to a seed crystal (almost

any small clump of material) and, as the temperature drops, more

and more ions are attracted in a regular pattern, thus creating

a crystal. This is, undoubtedly, a dynamic process where some materials

react and fall out of solution which allows more room for other

materials to go into solution.

Crystal found in Karen Starshine glaze slurry, ½” x

½”x ½”.

|

|

|

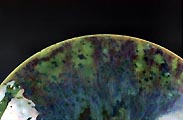

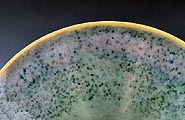

| Bowl with dried mix of Karen Starshine glaze, reduction, porcelain,

cone 10. (Front) |

Bowl with fresh mix of Karen Starshine glaze, reduction, Grolleg

porcelain, cone 10. (Front). |

Bowl with crystals found in Karen Starshine placed on rim,

reduction, Grolleg porcelain, cone 10, over clear glaze |

One interesting thing was that crystals did not occur in all the

glazes that contained borates and lithium oxide. Over half of the

80 copper red recipes tested had no crystals, suggesting that there

are factors influencing crystal formation other than cooling, evaporation,

and the availability of soluble borates, sodium and lithium oxide.

One possibility could be variations in pH or the glazes.

The pH value of a solution refers to its acidity or alkalinity.

This often stems from a material’s ability to go into solution

rather than stay in suspension. Since multiple materials are used

in a glaze, the pH of one material can affect the ability of other

materials to go into solution. For example, barium carbonate is

listed as insoluble in pure water but glaze slops can be slightly

acidic (flocculated) and in those cases barium carbonate can be

slightly soluble. Materials that are slightly soluble will dissolve

in the glaze slop into extremely small charged particles, or ions.

These small dissolved ions can greatly affect the condition of

the glaze slop, and may cause it to become flocculated or deflocculated

and thus more difficult to handle. Plant or wood ash, for example,

which is high in soluble salts, if used straight from the hearth

can easily deflocculate a glaze slop, making it too thin. To avoid

this and provide consistency, ash can be washed before being used.

Flocculants, like Epsom salts, cause the glaze slop to gel or thicken,

which may make the application too thick, resulting in cracking

as it dries. Flocculation and deflocculation are not bad in themselves;

they are merely conditions of a glaze slop. Some glazes are purposely

deflocculated to aid in spraying or brushing, or flocculated to

help keep particles suspended. It only becomes a problem if it is

out of control.

|

|

|

| Larger crystal found in slurry, 3” x 2 ½”x

½’. |

Soda ash crystals grown in saturated solution, 3” x

3” x 3”. |

Tri-sodium phosphate crystals grown in saturated solution,

3” x 1” x 1”. |

Handling soluble materials

Frits, created partly to avoid solubility problems associated

with some materials or to make toxic materials such as lead safer

to handle, are manufactured by taking soluble materials and mixing

them with clay, silica or a variety of other oxides, firing them

to melting point and pouring them into water to make them shatter

before grinding into a powder. Nevertheless, some frits, such as

the alkali, remain slightly soluble, in spite of, being labelled

as insoluble.

Soluble materials need careful attention. Those dissolved in the

glaze slop will be lost if water is poured off to thicken the glaze

slurry. They will also migrate into the bisque ware as a glazed

pot dries, which can affect the clay body because some of the fluxing

oxides will remain there. They can also make the final look of the

glaze difficult to control because the drying process often creates

uneven concentrations of these materials, depending on where the

water is evaporating. These are all sound reasons to avoid using

them.

However, by excluding them we risk missing some remarkable effects.

Carbon trap shinos and self-glazing clays like, Egyptian paste,

both depend on the migration of soluble salts to create their characteristic

look. And now we see that soluble materials in our glaze slurry

can crystallize from cooling the glaze slurry, which, because of

the uneven concentrations of oxides in the crystal formations, can

cause beautiful and unusual glaze surfaces.

|

|

|

|

| Crystal found in Splotchy Lavender glaze slurry 2” x

1” x1”. |

Crystals found in Splotchy Lavender placed on rim, reduction,

Grolleg porcelain, cone 10. |

Bowl with crystals found in Splotchy Lavender placed on rim,

reduction, Grolleg porcelain, cone 10. |

|

Crystals will also form if glaze slurries containing soluble materials

are allowed to dry out completely. As the water evaporates the soluble

ingredients form small crystals, which may be seen on the sides

of the bucket and on the surface of the dried glaze. Once the glaze

is fully dried you can add water and allow it to rehydrate. Using

it without sieving or grinding up the chunks can result in some

interesting surfaces. I have done this with carbon trap shinos and

Karen’s Starshine (Images 13, 14). Many potters may be experiencing

this effect without realizing it, as we often allow our glazes to

dry out when not in use. Then, in a rush to glaze something, we

re-wet and apply them, often without sieving.

Crystal growth is easily demonstrated by saturating water with

a soluble material and then cooling it. I grew some examples, such

as soda ash and tri-sodium phosphate crystals (Images 11, 12). For

those interested, the book “Crystal and Crystal Growing”,

by Holden and Morrison is very helpful in explaining the crystals

and practical ways to grow them.

Glazing and firing is an already complex process and discovering

that crystals can grow in glaze slops adds yet another variable.

We know that our glaze materials and kiln atmospheres are in constant

flux but so to may be the glaze slurry itself. These crystal formations,

some virtually invisible, could be causing migration of oxides within

the slurries that dramatically affect the outcome of the glaze appearance.

Since ancient potteries did not have modern heating technologies,

it is possible that some unique historic glaze effects may have,

inadvertently, been the result of crystallization of soluble oxides

in their glaze slops.

John Britt’s book The Complete Guide to High-Fire Glazes:

Glazing and Firing at Cone 10 is published by Lark Books/Sterling

Publishing, It can be purchased from John Britt’s website

for $25.00 USD plus shipping ($5.00 U.S. and $20.00 International)

at: www.johnbrittpottery.com.

Glaze recipe chart. (Please note: * asterisks

indicate * TOXIC materials).

| . |

Splotchy Lavender |

Lavender |

Mary's Surprise |

Jeff's Red |

Red Flambe |

Karen Starshine |

VC Matte Turquoise |

| Custer Feldspar |

50 |

49 |

45.9 |

41.9 |

34 |

. |

. |

| K-200 Feldspar |

. |

. |

. |

. |

. |

51 |

. |

| Nepheline Syenite |

. |

. |

. |

. |

. |

. |

44.4 |

| Cornwall Stone |

. |

. |

. |

. |

9.7 |

. |

. |

| Whiting |

14 |

13.7 |

12.9 |

8.4 |

17.5 |

13 |

8.9 |

| Silica |

20 |

23.5 |

27.5 |

26.2 |

19.4 |

21 |

15.6 |

| Kaolin |

. |

2.1 |

. |

. |

6.8 |

. |

11.1 |

| Gerstley Borate |

. |

. |

6.4 |

8.7 |

1.9 |

6 |

11.1 |

| Frit 3134 |

7 |

4.2 |

. |

. |

. |

. |

. |

| Dolomite |

. |

. |

. |

8.7 |

. |

. |

. |

| Barium Carbonate* |

2 |

1.5 |

. |

4.4 |

. |

4 |

. |

| Strontium Carbonate |

. |

. |

1.8 |

. |

. |

. |

. |

| Lithium Carbonate* |

2 |

1.9 |

1.8 |

. |

. |

1 |

8.9 |

| Borax |

. |

. |

. |

. |

9.7 |

. |

. |

| Bone Ash |

. |

. |

. |

. |

1 |

. |

. |

| Soda Ash |

. |

. |

. |

. |

. |

4 |

. |

| Zinc Oxide* |

4 |

3.9 |

3.7 |

1.7 |

. |

. |

. |

|

. |

. |

. |

. |

. |

. |

. |

| Tin Oxide |

1 |

0.9 |

1 |

2.6 |

. |

. |

. |

| Copper Carbonate* |

0.6 |

0.5 |

0.35 |

0.5 |

0.25 |

5 |

1.7 |

| Rutile |

. |

0.1 |

. |

. |

1.5 |

. |

. |

| Titanium Dioxide |

. |

. |

. |

. |

. |

4 |

11.1 |

| Red Iron Oxide |

. |

0.2 |

. |

. |

0.5 |

. |

. |

| Bentonite |

1 |

1 |

2 |

1 |

. |

. |

. |

More Articles

|