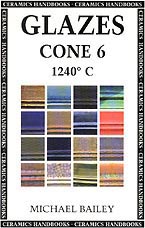

| Glazes Cone 6

by Michael Bailey

Having recently reviewed another book on cone 6 glazes on this

site, it is interesting to have the opportunity to have a look at

another publication - albeit quite a different one - on the topic

- Glazes Cone 6, by British potter and Bath Potters Supplies

partner Michael Bailey.

This publication appears as part of the well known "Ceramics

Handbook" series, which covers various topics on ceramics ranging

from paperclay to decals to kiln building and more. This series

is published in the US by the University of Pennsylvania Press,

Philadelphia.

Bailey's

book on cone 6 glazes concentrates on this temperature range in

oxidation. This has the advantage that anyone with a kiln - gas

or electric - can benefit from the knowledge and glazes that this

book has to offer. It has the disadvantage of omitting the interesting

field of cone 6 reduction glazes. Perhaps a small chapter on this

topic could have been included, possibly with some information on

artificial reduction glazes with silicon carbide, to the benefit

of those with electric kilns. Bailey's

book on cone 6 glazes concentrates on this temperature range in

oxidation. This has the advantage that anyone with a kiln - gas

or electric - can benefit from the knowledge and glazes that this

book has to offer. It has the disadvantage of omitting the interesting

field of cone 6 reduction glazes. Perhaps a small chapter on this

topic could have been included, possibly with some information on

artificial reduction glazes with silicon carbide, to the benefit

of those with electric kilns.

However the book does deliver handsomely on many other fronts.

Included are a number of useful base glazes: transparent, matt,

alkaline, crystalline, chun, luster and others. To top it off, there

is a chapter on raw glazes. All in all, there are about 40 'base

glazes' for which recipes are given. Add to this variations with

coloring oxides - mainly iron, cobalt, nickel, manganese and titanium,

and we arrive at a huge database of cone 6 glazes.

Backing up this research is a sound theoretical framework, which

should help the reader to better understand the scientific and technical

issues concerning glazes in general and cone 6 in particular. Covered

are: the effects of clay bodies on glazes, the unity formula and

percentage analysis, alumina-silica ratios etc. A chapter on Glaze

Fit explains coefficients of expansion as well as common glaze defects

such as crazing, shivering and dunting and gives advice on alleviating

these problems.

An interesting last chapter is the "Gallery", where Bailey

offers images and explanations of cone 6 works of about a dozen

fellow potters. This is followed by some addresses where we can

find helpful info on glazes and related issues on the internet.

Topping off this publication is an appendix, which includes 'Analysis

of Materials', a glossary, a list of suppliers and a bibliography

for those wanting to do further research.

Conclusion:

There are compelling arguments for wanting to work in the cone 6

range - stoneware effects can be achieved at a lower, cost-cutting,

more environmentally friendly temperature. Wear and tear on kilns

is reduced, as are firing times. Glazes Cone 6 adds valuable

information to the repository of general knowledge on glazes for

this temperature range, while at the same time offering us a gamut

of glazes to try out and experiment with. My greatest criticism

is that little is said about the important issue of glaze stability

and possible leaching of glaze components in functional wares used

with food. Readers concerned with this are referred to the book

Mastering Cone 6 Glazes, which makes

a good companion book to Bailey's Glazes Cone 6.

More Reviews

|