| The Alchemy of Watercolors On Porcelain - Part I

here

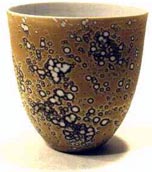

is something enigmatic about the 'Watercolors on Porcelain' technique.

The elusive colors, that may or may not be as expected; the transmutation

in the fire -to get that most precious, beautiful surface. The parallels

with alchemy of the Middle Ages certainly are there: European porcelain

was 'discovered' by the German Alchemist Johann Friedrich Boettger

around 1709, after numerous vain attempts to copy Chinese Porcelain

in the 15th, 16th and 17th centuries. There is the use of precious

metals -gold, silver, rhodium, palladium; the transformation in

the high temperature firing; the knowledge of the underlying chemical

processes; the chance discoveries... While it is not gold that we

are trying to discover (although precious metals including gold

may be used), the 'Watercolors on Porcelain' technique is still

used by relatively few. This has its reasons -some of the raw materials

are prohibitively expensive, they are highly toxic and necessitate

extreme care, the results are not always promising and more research

needs to be undertaken, despite knowledge already pioneered by others. here

is something enigmatic about the 'Watercolors on Porcelain' technique.

The elusive colors, that may or may not be as expected; the transmutation

in the fire -to get that most precious, beautiful surface. The parallels

with alchemy of the Middle Ages certainly are there: European porcelain

was 'discovered' by the German Alchemist Johann Friedrich Boettger

around 1709, after numerous vain attempts to copy Chinese Porcelain

in the 15th, 16th and 17th centuries. There is the use of precious

metals -gold, silver, rhodium, palladium; the transformation in

the high temperature firing; the knowledge of the underlying chemical

processes; the chance discoveries... While it is not gold that we

are trying to discover (although precious metals including gold

may be used), the 'Watercolors on Porcelain' technique is still

used by relatively few. This has its reasons -some of the raw materials

are prohibitively expensive, they are highly toxic and necessitate

extreme care, the results are not always promising and more research

needs to be undertaken, despite knowledge already pioneered by others.

Just what is WOP? (I shall use this acronym from now on). As most

readers will know, the majority of traditional ceramic colors come

in the form of oxides or carbonates that are used in underglazes,

onglazes and as slip and glaze additives. From these oxides and

carbonates come the broad palette of decorative effects that we

have known for centuries, even millennia. In the late 1980's, Professor

Arne Åse investigated the use of watersoluble metal salts,

derivatives of the oxides and carbonates, for color effects and

possible applications in studio ceramics. He chose to test these

substances on porcelain, as the whiteness of this particular clay

should give the most untainted color response. Thus the WOP technique

was born.

Just what is WOP? (I shall use this acronym from now on). As most

readers will know, the majority of traditional ceramic colors come

in the form of oxides or carbonates that are used in underglazes,

onglazes and as slip and glaze additives. From these oxides and

carbonates come the broad palette of decorative effects that we

have known for centuries, even millennia. In the late 1980's, Professor

Arne Åse investigated the use of watersoluble metal salts,

derivatives of the oxides and carbonates, for color effects and

possible applications in studio ceramics. He chose to test these

substances on porcelain, as the whiteness of this particular clay

should give the most untainted color response. Thus the WOP technique

was born.

Which chemicals are we actually talking about? As already mentioned,

they are watersoluble metal salts: chlorides, sulphates and nitrates

of some common and other not so common metals, eg. Gold Chloride,

Nickel Sulphate or Iron Nitrate. In most cases there will be a chloride,

nitrate and sulphate version of a given metal available, eg. Copper

Chloride, Copper Nitrate and Copper Sulphate. There are also some

useful colorants that aren't actually metallic salts, but nonetheless

watersoluble, eg. Potassium Dichromate. Being watersoluble, these

chemicals will react in a different way when applied to a clay surface.

Instead of sitting on the surface they will stain and penetrate

the clay, sometimes going right through to the other side, so some

unexpected results can be reckoned with!

While a fair amount of research has been done with the chlorides

and nitrates, I think the sulphates have been overlooked somewhat.

The fact that Iron Sulphate, Cobalt Sulphate and Copper Sulphate

were readily available and relatively inexpensive led me to investigate

these chemicals. I'd also like to talk about Gold Chloride, Potassium

Dichromate and to a degree Uranyl Nitrate, plus the effects of resist

materials and the use of Phosphoric Acid. These materials can sometimes

be bought from potters suppliers, some will need to obtained from

a supplier to laboratories. For our purpose, the grade or purity

need not be high. Generally they will be supplied in a powder or

crystalline form from which a solution must be made. When dealing

with these chemicals it is advisable to wear thick rubber gloves,

a mask with gas attachments and also goggles to protect the eyes.

Eating or drinking anywhere near these chemicals is of course out

of the question (and something one shouldn't do near ceramic materials

anyway). A few other things will be necessary: some glass jars that

will not leak (food jars aren't good enough!); a chemists measuring

tumbler, with measurements from 1 to 50 ml; an accurate set of scales,

with 1 gm gradations. All decoration is carried out on bisqued ware

and then fired to approximately 1270 degrees celsius in a reduction

atmosphere.

While a fair amount of research has been done with the chlorides

and nitrates, I think the sulphates have been overlooked somewhat.

The fact that Iron Sulphate, Cobalt Sulphate and Copper Sulphate

were readily available and relatively inexpensive led me to investigate

these chemicals. I'd also like to talk about Gold Chloride, Potassium

Dichromate and to a degree Uranyl Nitrate, plus the effects of resist

materials and the use of Phosphoric Acid. These materials can sometimes

be bought from potters suppliers, some will need to obtained from

a supplier to laboratories. For our purpose, the grade or purity

need not be high. Generally they will be supplied in a powder or

crystalline form from which a solution must be made. When dealing

with these chemicals it is advisable to wear thick rubber gloves,

a mask with gas attachments and also goggles to protect the eyes.

Eating or drinking anywhere near these chemicals is of course out

of the question (and something one shouldn't do near ceramic materials

anyway). A few other things will be necessary: some glass jars that

will not leak (food jars aren't good enough!); a chemists measuring

tumbler, with measurements from 1 to 50 ml; an accurate set of scales,

with 1 gm gradations. All decoration is carried out on bisqued ware

and then fired to approximately 1270 degrees celsius in a reduction

atmosphere.

Cobalt Sulphate

A useful concentration for Cobalt Sulphate is about 10%. To make

this, we weigh 10 gms of Cobalt Sulphate powder and add it to 100

ml of water. I have previously used distilled water, but this isn't

really necessary unless your tap water is really impure. Carefully

add the powder to the water without spilling any. This should be

done wearing a good mask with gas filter and good rubber gloves

that are impervious to water and definitely not inside any living

quarters. Brushes must be washed well in running water and not used

for any other purpose. Always ensure there are a few layers of newspaper

underneath the work to avoid soiling the working area. If anything

is ever spilt, clean it up immediately and thoroughly. Never reuse

cleaning utensils such as sponges.

The solution is now ready to be applied. This can be done with

a brush, freehand or on the wheel. Protect any bench surfaces or

wheel heads with newspaper. Just how many layers of solution should

be brushed on is a matter of finding out what works for you, as

the result also depends on the type of brush you are using and on

the density of the clay. Spraying is not recommended as it can be

messy, even with a spraying booth. One of the greatest difficulties

in applying these chemicals is the fact that they are very hard

to see once painted on. One way to get around this would be to add

ink or food colorants to the liquids.

After applying the Cobalt Sulphate, I sometimes apply a layer

of Uranyl Nitrate over the top, also with a brush, in a concentration

of 7.5%. The greatest care needs to be taken with this chemical,

it is highly toxic! After a short drying time, Phosphoric Acid (85%

concentration) can be applied to achieve the 'halo' effect. Of course

great care also needs to be taken when handling the acid - goggles

should be worn! The effect of the Phosphoric Acid is to displace

the colors and concentrate them on the edge. This will often reveal

the white color of the underlying porcelain.

Next > The Alchemy

of Watercolors On Porcelain > 2

More Articles

|